Discovering the Best Torque Flexible Coupler Supplier for Your Needs

In the world of precision engineering and mechanical systems, finding a reliable torque flexible coupler supplier is essential for ensuring seamless operations in demanding applications. A torque flexible coupler supplier provides components that absorb shocks, compensate for misalignments, and transmit torque efficiently between shafts, making them indispensable in industries like automation, robotics, and manufacturing. As servo motors and high-torque systems become more prevalent, partnering with a trusted torque flexible coupler supplier can significantly enhance system performance and longevity. These suppliers specialize in flexible shaft connectors that eliminate backlash and deliver precise motion control, turning complex engineering challenges into reliable solutions.

Key Features of High-Quality Torque Flexible Couplers

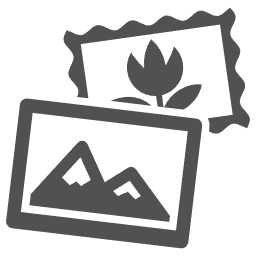

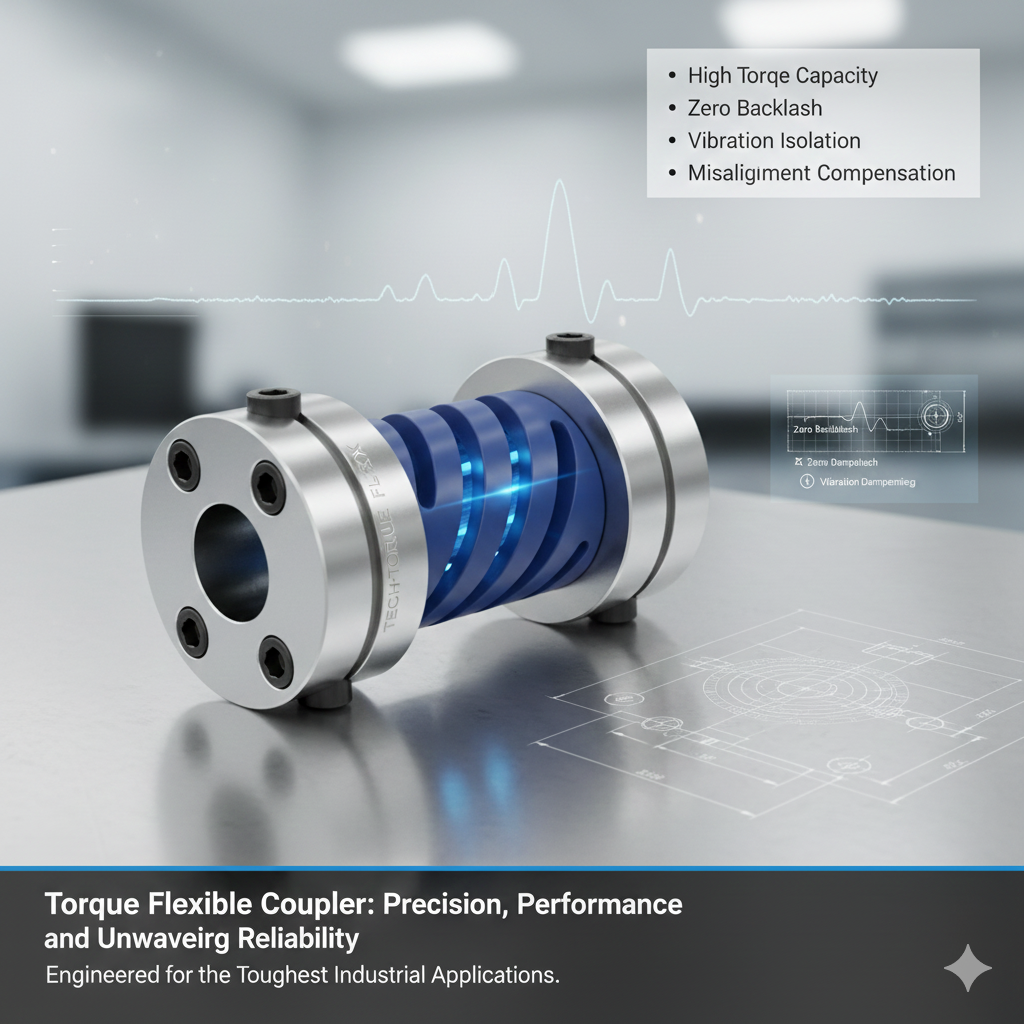

When selecting a torque flexible coupler supplier, it's crucial to understand the core features that make their products stand out. Precision motion control is at the heart of these devices, offering zero backlash and exceptional torsional stiffness. This means that every rotation is accurate, with no mechanical delays that could compromise efficiency. The interlocking gears in these couplers ensure stability, reducing unwanted vibrations and maintaining top-notch precision across various loads. A reputable torque flexible coupler supplier will emphasize dynamic torque transfer, allowing for seamless power transmission in high-torque servo motor setups. This eliminates jerky motions, enabling smooth and continuous operation that boosts overall system productivity. Moreover, these couplers excel in vibration damping, which minimizes noise and extends the lifespan of connected machinery, making them ideal for sensitive environments.

Applications Across Critical Industries

The versatility of products from a top torque flexible coupler supplier shines in critical OEM applications. In robotics, these couplers provide the precision needed for intricate movements, ensuring robots perform tasks with unerring accuracy. Medical equipment benefits from their misalignment compensation, which maintains reliability in devices like surgical robots where even minor deviations can have serious consequences. Automation lines in manufacturing see enhanced efficiency, as the flexible shaft connectors handle high-torque demands without faltering, streamlining assembly processes. In the printing industry, they contribute to smooth paper handling and precise color registration, reducing downtime and waste. By choosing a dedicated torque flexible coupler supplier, businesses can integrate these components into systems that demand both power and finesse, transforming operational workflows into models of efficiency.

Why Choose a Specialized Torque Flexible Coupler Supplier

Partnering with a specialized torque flexible coupler supplier offers more than just quality parts; it provides engineering expertise tailored to your specific needs. These suppliers often focus on harmonic drive reliability, ensuring that couplers withstand real-world variables like thermal expansions or slight shaft misalignments without losing performance. This level of engineering for smooth accuracy means reduced maintenance costs and fewer unexpected failures in high-stakes environments. For instance, in advanced servo motor applications, the supplier's products facilitate fluid power transfer, supporting loads that range from light-duty automation to heavy industrial machinery. Additionally, their commitment to vibration damping helps in noise-sensitive settings, such as cleanroom operations or precision labs, where quiet and stable performance is non-negotiable. Selecting the right torque flexible coupler supplier also means access to customized solutions, where the design can be adapted to fit unique torque requirements, ultimately driving innovation and cost savings for OEMs.

Evaluating Your Torque Flexible Coupler Supplier

To make an informed decision, evaluate potential torque flexible coupler suppliers based on their track record in delivering consistent quality and support. Look for those who prioritize materials that offer durability, such as high-grade alloys or composites that resist wear under continuous operation. A good supplier will provide detailed specifications on torsional stiffness and backlash elimination, backed by testing data that verifies performance in real applications. Consider their responsiveness in customization—whether they can adjust coupler sizes or materials to match your servo motor's specifications. Furthermore, check for compliance with industry standards, ensuring the products meet ISO certifications for reliability. By focusing on these aspects, you ensure that your torque flexible coupler supplier not only meets current needs but scales with future expansions, providing a foundation for long-term mechanical success.

The Future of Torque Flexible Couplers in Engineering

Looking ahead, the role of a torque flexible coupler supplier in the engineering landscape is set to grow with advancements in automation and AI-driven systems. As industries push for higher precision and efficiency, these couplers will evolve to incorporate smart sensors for real-time monitoring of torque and alignment, preventing issues before they arise. Suppliers at the forefront will integrate sustainable practices, using eco-friendly materials that maintain performance without environmental impact. For servo motor integrations, this means even smoother torque transfer in dynamic environments like electric vehicles or renewable energy systems. By aligning with an innovative torque flexible coupler supplier, companies can future-proof their operations, embracing technologies that enhance precision while adapting to emerging challenges. Ultimately, these partnerships foster a ecosystem where mechanical reliability meets cutting-edge innovation, propelling industries forward.

In summary, securing a dependable torque flexible coupler supplier is key to unlocking the full potential of your mechanical systems. From precision control to robust applications, these components and the expertise behind them drive unparalleled performance. Whether you're in robotics, medical tech, or beyond, investing in quality flexible shaft connectors ensures efficiency and reliability that stand the test of time.