Discovering the Best Precision Universal Joint Supplier for Your Mechanical Needs

In the world of mechanical engineering, finding a reliable precision universal joint supplier is crucial for ensuring the smooth operation of complex systems. These components are vital for transmitting power between shafts that aren't perfectly aligned, and a top-tier precision universal joint supplier provides products that meet exacting standards for durability and performance. Whether you're in automotive manufacturing, industrial automation, or agricultural equipment design, partnering with the right precision universal joint supplier can make all the difference in your project's success.

Precision universal joints are engineered marvels that allow for flexible motion transfer while maintaining accuracy. As a leading precision universal joint supplier, we pride ourselves on delivering components that exceed industry expectations. Our universal joints are crafted to handle high torque and angular misalignments, making them indispensable in demanding applications. By sourcing from a trusted precision universal joint supplier, businesses can reduce downtime and enhance overall efficiency.

Understanding the Universal Joint Coupler: A Key Offering from Precision Universal Joint Suppliers

The Universal Joint Coupler stands out as a cornerstone product in the lineup of any reputable precision universal joint supplier. This innovative component is designed to connect two shafts efficiently, even when they are not collinear, ensuring seamless rotary motion transmission. Made from high-grade stainless steel, the Universal Joint Coupler offers exceptional resistance to corrosion and wear, which is essential for long-term reliability in harsh environments.

What sets the Universal Joint Coupler apart is its dual-axis flexibility, allowing it to accommodate angular misalignments up to 30 degrees without compromising performance. Equipped with precision-machined pins and secure retaining rings, this coupler from a quality precision universal joint supplier ensures easy assembly and minimal maintenance. Industries such as automotive repair and heavy machinery rely on these features to maintain operational integrity, preventing costly failures and breakdowns.

As a precision universal joint supplier, we understand the importance of customization. The Universal Joint Coupler can be tailored to specific shaft sizes and load requirements, providing versatility for diverse applications. From small-scale prototypes to large industrial setups, sourcing your Universal Joint Coupler from a dedicated precision universal joint supplier guarantees compatibility and superior functionality.

Why Choose a Trusted Precision Universal Joint Supplier for Industrial Applications

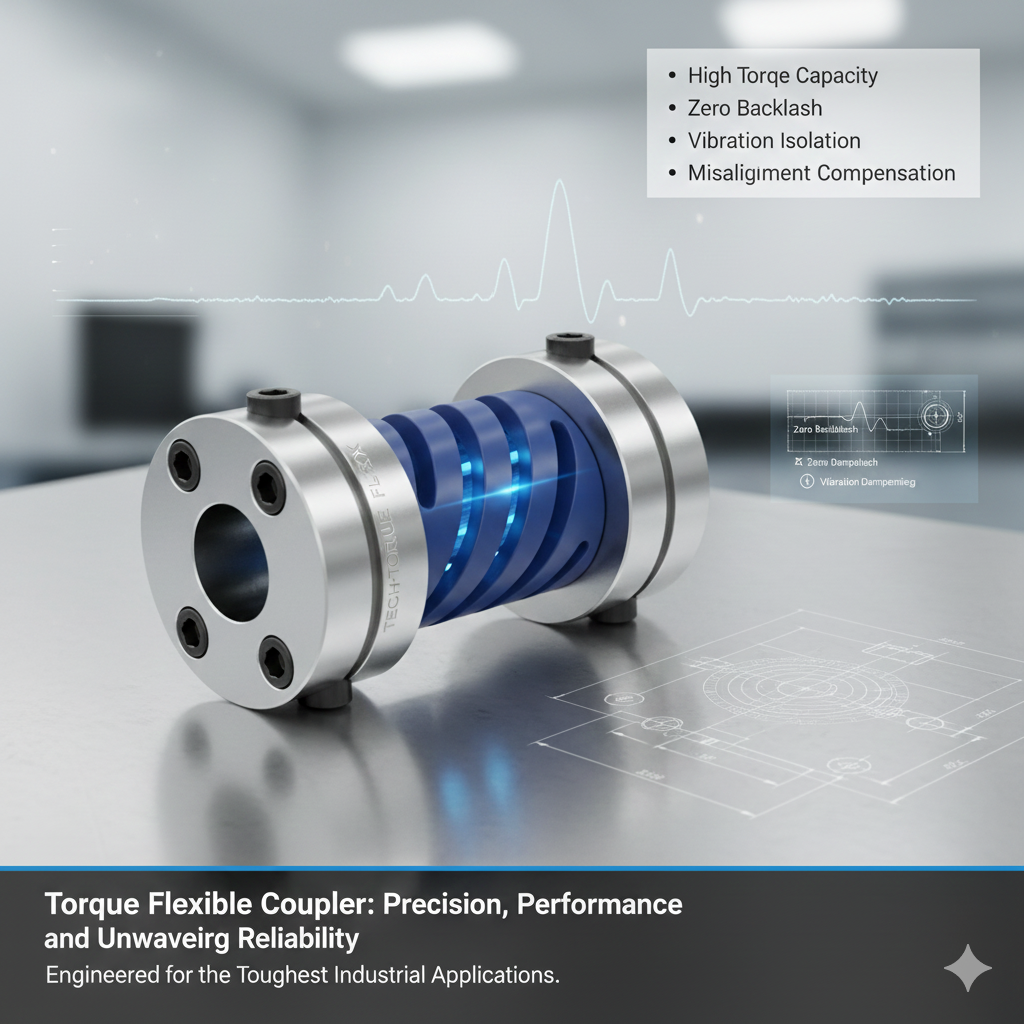

Selecting the right precision universal joint supplier is not just about product quality; it's about building a partnership that supports your entire operation. A reliable precision universal joint supplier offers not only high-performance components like the Universal Joint Coupler but also comprehensive technical support, including design consultations and after-sales service. This holistic approach ensures that your mechanical systems operate at peak efficiency, reducing the risk of misalignment issues that can lead to vibration, noise, or even catastrophic failure.

In automotive applications, for instance, precision universal joints are critical for drivetrain systems, where even minor deviations can affect vehicle handling and safety. By partnering with a precision universal joint supplier who specializes in automotive-grade materials, manufacturers can achieve the precision needed for smooth power delivery. Similarly, in industrial settings, these joints facilitate the connection of motors to pumps or conveyors, where reliability under continuous operation is paramount.

Agricultural machinery benefits immensely from robust offerings by a precision universal joint supplier. The Universal Joint Coupler, with its durable construction, withstands the rigors of fieldwork, including exposure to dust, moisture, and varying loads. Choosing a supplier committed to quality control means your equipment stays productive longer, ultimately lowering operational costs and boosting yield.

The Engineering Behind High-Quality Precision Universal Joints

At the heart of every precision universal joint supplier's product is advanced engineering that balances flexibility with strength. The design of components like the Universal Joint Coupler involves meticulous attention to tolerances, ensuring that the joint can transmit torque effectively while absorbing shocks and vibrations. High-grade stainless steel is selected for its superior tensile strength and resistance to fatigue, allowing these joints to perform consistently in high-stress environments.

Precision manufacturing techniques, such as CNC machining and heat treatment, are employed by top precision universal joint suppliers to achieve the exact specifications required. This results in joints that not only fit perfectly but also maintain their integrity over thousands of cycles. For example, the pins in the Universal Joint Coupler are hardened to prevent wear, and the retaining rings are designed for quick installation without specialized tools.

Beyond materials and machining, a precision universal joint supplier invests in rigorous testing protocols. Each batch of universal joints undergoes load testing, misalignment simulations, and environmental exposure assessments to verify performance. This commitment to quality assurance is what distinguishes leading suppliers, providing customers with confidence in their mechanical assemblies.

Applications and Benefits of Sourcing from a Precision Universal Joint Supplier

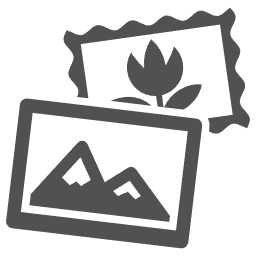

The versatility of products from a precision universal joint supplier extends across multiple sectors. In robotics and automation, precision universal joints enable precise movements in articulated arms, enhancing accuracy in assembly lines. The Universal Joint Coupler's ability to handle multidirectional forces makes it ideal for these dynamic applications, where downtime can be extremely costly.

For marine and aerospace industries, the corrosion-resistant properties of stainless steel universal joints are invaluable. A precision universal joint supplier catering to these fields ensures that components can endure extreme conditions, from saltwater exposure to high-altitude pressures. The result is safer, more reliable systems that meet stringent regulatory standards.

Benefits of choosing a dedicated precision universal joint supplier include cost savings through bulk purchasing options and just-in-time delivery, minimizing inventory overhead. Additionally, suppliers often provide value-added services like CAD drawings and prototype development, streamlining the integration process for engineers. Overall, investing in quality precision universal joints translates to enhanced system longevity and reduced maintenance needs.

Future Trends in Precision Universal Joint Technology

Looking ahead, the role of a precision universal joint supplier in innovation cannot be overstated. Emerging trends include the integration of smart sensors into universal joints for real-time monitoring of wear and alignment, allowing predictive maintenance. As materials science advances, we can expect even lighter yet stronger alloys, further improving efficiency in electric vehicle drivetrains and renewable energy systems.

Sustainability is another focus for forward-thinking precision universal joint suppliers. Eco-friendly manufacturing processes, such as recycling stainless steel scraps, are becoming standard, aligning with global environmental goals. The Universal Joint Coupler is evolving too, with designs that reduce friction and energy loss, contributing to greener operations.

By staying at the forefront of these developments, a precision universal joint supplier ensures clients receive cutting-edge solutions that future-proof their investments. Whether upgrading existing machinery or designing new prototypes, relying on an expert supplier positions businesses for long-term success in a competitive landscape.

In conclusion, partnering with a premier precision universal joint supplier unlocks a world of possibilities for mechanical engineering projects. From the robust Universal Joint Coupler to customized solutions, these suppliers deliver the precision and reliability needed to drive innovation and performance.