Discovering the Excellence of a High Precision Flexible Shaft Joint Manufacturer

In the world of advanced engineering and automation, finding a reliable high precision flexible shaft joint manufacturer is crucial for ensuring seamless performance in complex systems. These specialized components are the backbone of precision machinery, allowing for accurate power transmission and motion control in demanding applications. As industries evolve, the demand for high-quality flexible shaft joints has surged, particularly in sectors like robotics, medical devices, and automation. A top-tier high precision flexible shaft joint manufacturer focuses on innovation, delivering products that minimize backlash and maximize efficiency. This article delves into the key aspects of what makes these manufacturers stand out, exploring their role in modern manufacturing and why their expertise is indispensable.

The Precision Motion Control Advantage

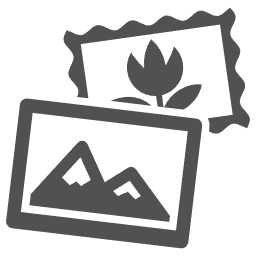

One of the hallmark features provided by a leading high precision flexible shaft joint manufacturer is precision motion control. These joints are engineered with zero backlash and enhanced torsional stiffness, which means they eliminate any unwanted play in movements, ensuring systems operate with exceptional accuracy. For instance, in robotics and automation systems, where every millisecond and micrometer counts, this level of precision can make or break operational success. High precision flexible shaft joints are designed to handle intricate tasks without compromising on reliability, making them ideal for environments that require unwavering accuracy. Manufacturers in this field invest heavily in research and development to refine these components, using advanced materials and cutting-edge machining techniques to achieve tolerances that surpass industry standards. This dedication to detail not only enhances performance but also extends the lifespan of the integrated machinery, reducing long-term costs for end-users.

Beyond the basics, a high precision flexible shaft joint manufacturer emphasizes customization to meet specific application needs. Whether it's adapting to high-speed operations or low-torque scenarios, these joints can be tailored to fit seamlessly into existing setups. The result is smoother operation and fewer errors, which translates to higher productivity. In the competitive landscape of manufacturing, partnering with such a specialist ensures that your projects benefit from components that are not just functional but transformative. As technology advances, these manufacturers continue to push boundaries, incorporating feedback from real-world applications to iterate on designs that anticipate future challenges.

Dynamic Torque Transfer and Efficiency

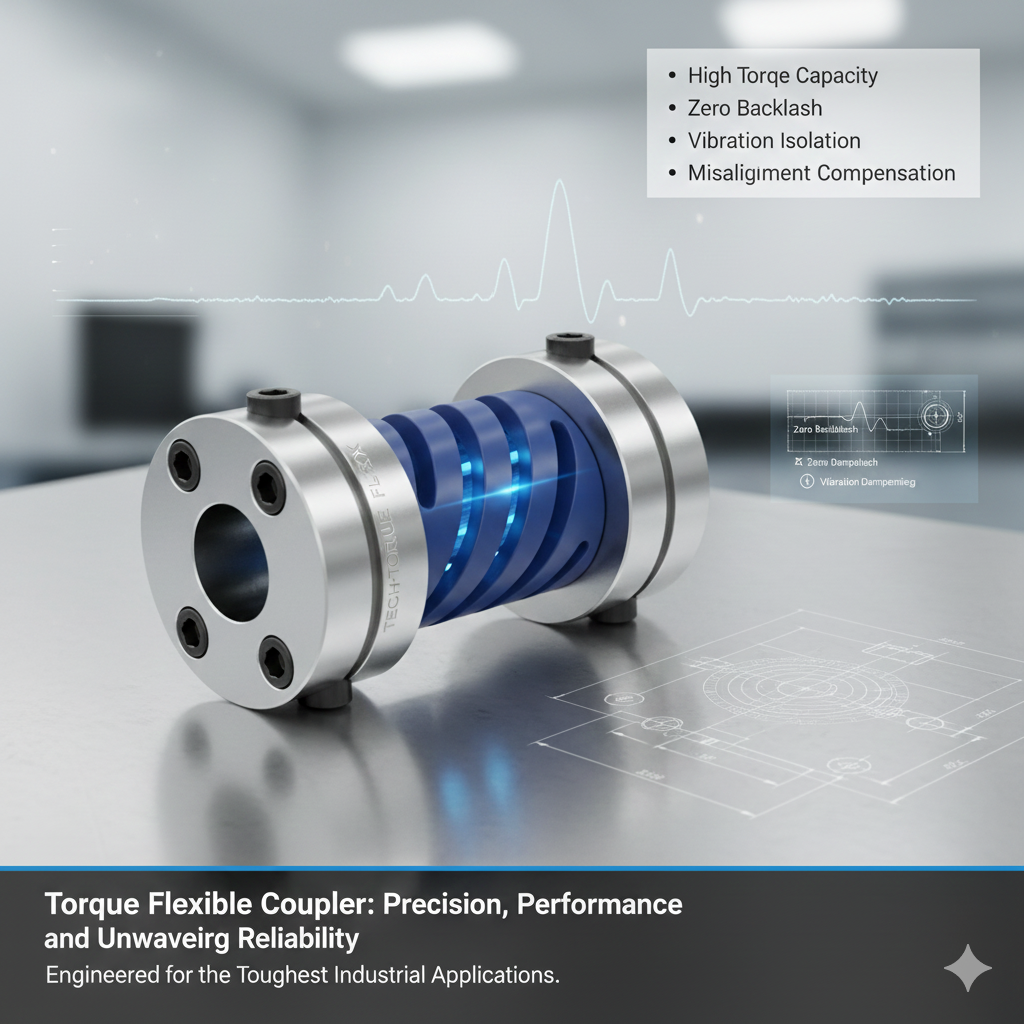

Dynamic torque transfer is another critical area where a high precision flexible shaft joint manufacturer excels. This capability ensures seamless power transmission from the motor to the driven component, facilitating uninterrupted and efficient energy flow. In high-performance environments like medical devices and printing machinery, consistent power delivery is non-negotiable. High precision flexible shaft joints are built to handle varying loads without slippage or loss of efficiency, which is vital for maintaining the integrity of the entire system. Manufacturers achieve this through meticulous engineering, focusing on materials that offer high strength-to-weight ratios and resistance to fatigue.

What sets these products apart is their ability to adapt to dynamic conditions. For example, in printing applications, where rapid movements and precise alignments are required, a well-crafted flexible shaft joint prevents vibrations that could lead to misalignment or print defects. Similarly, in medical devices, the reliability of these joints ensures patient safety by supporting consistent and predictable motion. A reputable high precision flexible shaft joint manufacturer conducts rigorous testing, including torque simulations and endurance trials, to validate performance under extreme conditions. This proactive approach not only builds trust but also positions their products as the go-to solution for original equipment manufacturers (OEMs) seeking to elevate their offerings.

Moreover, the efficiency gains from these joints extend to energy savings. By minimizing frictional losses, they help reduce power consumption, which is increasingly important in sustainable manufacturing practices. As companies strive to meet environmental goals, selecting components from a high precision flexible shaft joint manufacturer that prioritizes efficiency becomes a strategic decision. The integration of such joints can lead to optimized workflows, fewer downtimes, and overall cost reductions, making them a smart investment for forward-thinking businesses.

Versatility in Critical OEM Applications

High precision flexible shaft joints are indispensable in critical OEM applications, serving as the ideal choice for industries ranging from robotics to automation systems. A specialized high precision flexible shaft joint manufacturer designs these components to integrate seamlessly, providing the versatility needed across diverse fields. In robotics, for example, the joints enable fluid, multi-axis movements that mimic human dexterity, enhancing the capabilities of collaborative robots in assembly lines. For medical devices, their precision ensures delicate procedures are performed with minimal risk, supporting innovations in minimally invasive surgeries and diagnostic equipment.

In printing machinery, the reliability of these joints contributes to high-speed, high-resolution outputs without compromising quality. Automation systems benefit from their ability to compensate for misalignments, which is common in industrial setups where components may shift over time. By offering robust solutions that address these challenges, a high precision flexible shaft joint manufacturer becomes an invaluable partner in the design and manufacturing process. Their products are not one-size-fits-all; instead, they provide modular options that can be scaled or modified based on project specifications, allowing OEMs to innovate without limitations.

The breadth of applications underscores the manufacturer's commitment to quality and adaptability. Whether it's enduring the rigors of 24/7 operations in factories or meeting stringent regulatory standards in healthcare, these joints deliver consistent results. As global supply chains demand more resilient components, partnering with a high precision flexible shaft joint manufacturer ensures that your production lines remain agile and competitive. This level of integration fosters long-term collaborations, where manufacturers offer not just products but also technical support and consultation to optimize system performance.

Engineered for Smooth Accuracy and Longevity

Finally, the engineering behind high precision flexible shaft joints focuses on smooth accuracy, boasting superior vibration damping, misalignment compensation, and overall reliability. These features combine to minimize operational disruptions, enhance machine life, and reduce maintenance needs. A high precision flexible shaft joint manufacturer achieves this through innovative designs that incorporate harmonic drive principles, ensuring that even under heavy loads, the joints maintain their integrity. Vibration damping, in particular, is crucial for noise-sensitive environments like laboratories or precision assembly areas, where unwanted oscillations can lead to inaccuracies.

Misalignment compensation allows the joints to absorb angular and parallel offsets without transmitting stress to connected parts, preventing premature wear. This is especially beneficial in dynamic systems where perfect alignment is challenging to maintain. Reliability is further bolstered by the use of corrosion-resistant materials and precision machining, which guard against environmental factors. As a result, systems equipped with these joints experience fewer failures, leading to uninterrupted operations and substantial savings in repair costs.

Looking ahead, the evolution of high precision flexible shaft joint manufacturing is geared toward smarter, more connected components. Integration with IoT sensors for real-time monitoring is on the horizon, allowing predictive maintenance and even greater efficiency. By choosing a high precision flexible shaft joint manufacturer that embraces these advancements, businesses can future-proof their operations. In essence, these joints represent more than just mechanical links; they are enablers of innovation, driving industries toward higher standards of performance and precision.

In conclusion, the role of a high precision flexible shaft joint manufacturer cannot be overstated in today's technology-driven world. From precision motion control to dynamic torque transfer, their products empower critical applications with unmatched reliability. As we continue to push the boundaries of what's possible in engineering, these manufacturers remain at the forefront, crafting solutions that deliver both performance and peace of mind. For any project requiring exacting standards, turning to a trusted high precision flexible shaft joint manufacturer is the key to unlocking superior results.