Discovering the Excellence of a Double Cardan Universal Joint Factory

In the world of precision engineering, a double cardan universal joint factory stands as a beacon of innovation and reliability. This specialized facility is dedicated to producing high-quality double cardan universal joints, components essential for transmitting power smoothly across varying angles in machinery. These joints, also known as double Cardan joints, provide enhanced stability and reduced vibration compared to single joints, making them indispensable in automotive, agricultural, and industrial applications. At the heart of such a factory lies a commitment to craftsmanship, where every piece is meticulously designed to meet rigorous standards. Whether you're involved in heavy equipment manufacturing or seeking reliable parts for custom builds, understanding the operations of a double cardan universal joint factory can illuminate the superior quality behind these vital mechanical elements.

The Engineering Behind Double Cardan Universal Joints

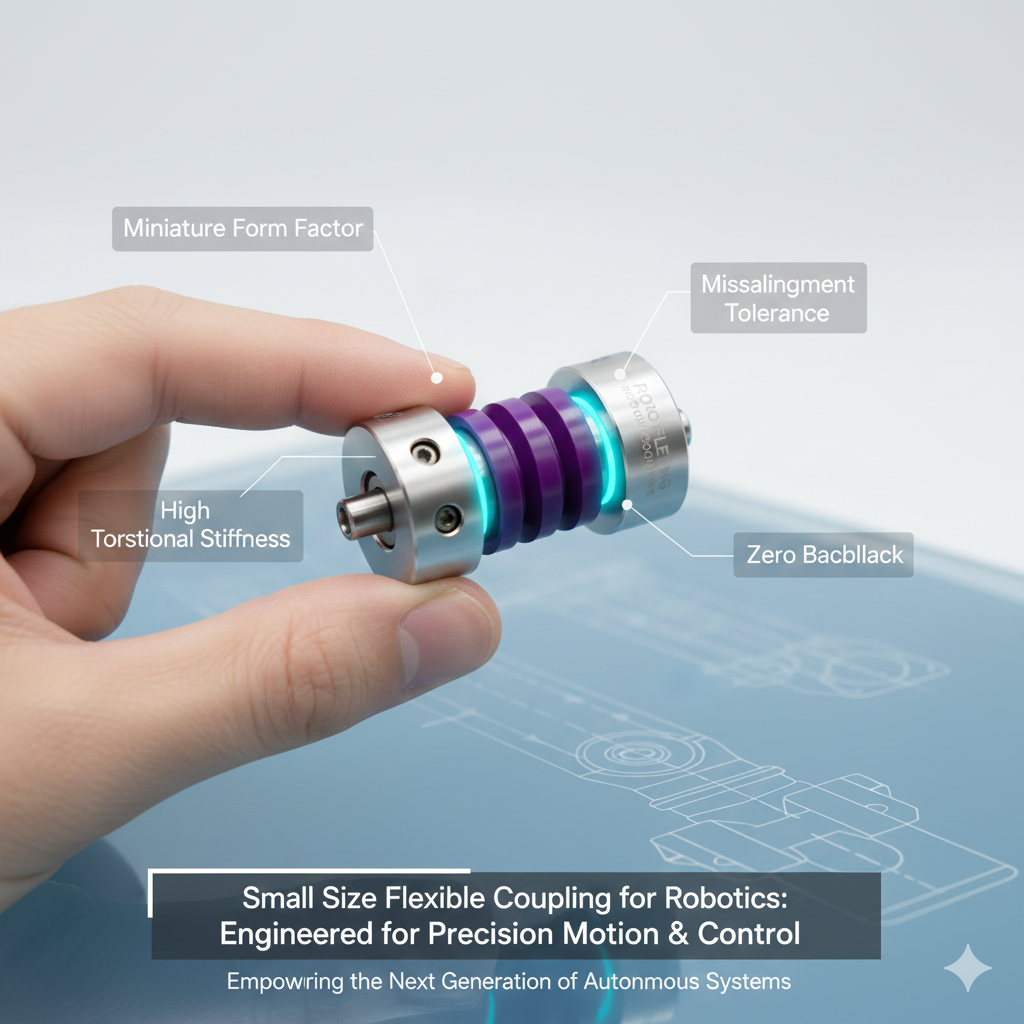

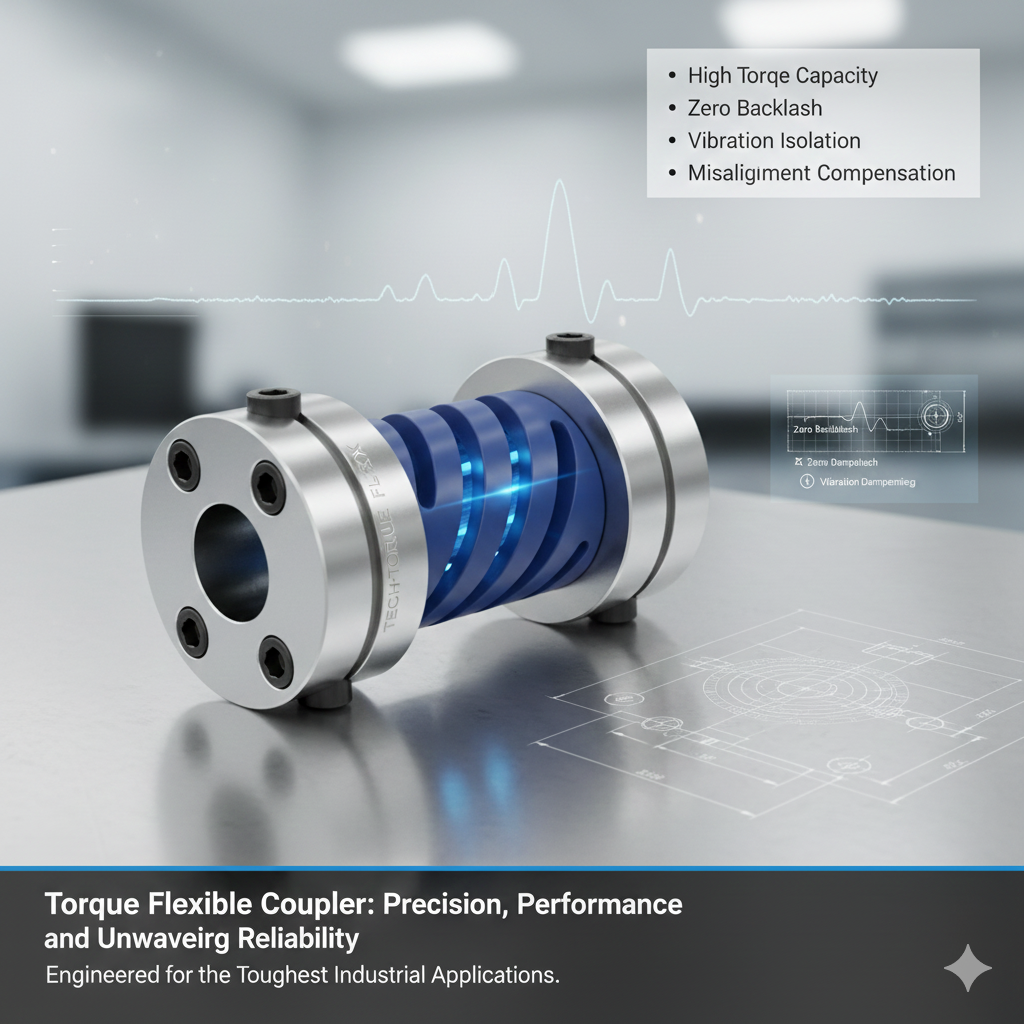

Delving deeper into the mechanics, a double cardan universal joint factory focuses on creating joints that consist of two universal joints connected by an intermediate shaft. This configuration allows for a constant velocity ratio, which is crucial in applications where misalignment between shafts is common. Factories like this employ state-of-the-art CNC machining and automated assembly lines to ensure precision. Materials such as high-strength alloy steel or stainless steel are selected for their durability and resistance to fatigue, enabling the joints to withstand high torque and harsh environments. The production process begins with the forging of yokes and crosses, followed by heat treatment to enhance tensile strength. Quality control measures, including dimensional inspections and torque testing, are integral, ensuring that each double cardan universal joint leaving the factory performs flawlessly. This level of detail not only extends the lifespan of machinery but also minimizes downtime, a key concern for industries relying on uninterrupted operations.

Applications and Advantages in Modern Industries

The versatility of products from a double cardan universal joint factory extends across numerous sectors. In the automotive industry, these joints are pivotal in drive shafts, providing smooth power delivery to wheels even during sharp turns. Agricultural machinery benefits from their robustness, handling the vibrations from uneven terrain without compromising efficiency. In industrial settings, such as conveyor systems or robotic arms, the double cardan design offers superior angular compensation, reducing wear on connected components. One major advantage is the elimination of speed fluctuations, which can lead to uneven power transmission in single joints. Factories emphasize customization, allowing for variations in size, load capacity, and sealing options to suit specific needs. For instance, grease fittings and protective boots are often incorporated to prevent contamination, extending service intervals. By choosing joints from a reputable double cardan universal joint factory, businesses can achieve cost savings through lower maintenance and higher operational reliability.

Quality Assurance and Innovation in Production

A hallmark of any leading double cardan universal joint factory is its unwavering focus on quality assurance. Advanced testing protocols, including non-destructive testing and simulation software, verify that each joint meets or exceeds international standards like ISO 9001. Innovation drives the industry forward, with factories investing in R&D to develop joints that incorporate lightweight materials without sacrificing strength, or designs that integrate sensors for real-time monitoring. Sustainability is also a growing priority, with efforts to reduce waste through efficient manufacturing processes and recyclable materials. Workers in these factories are highly skilled, often trained in the nuances of joint assembly to ensure perfect alignment of the centering ball and socket mechanism, which is critical for the double Cardan's performance. This blend of tradition and technology results in products that not only meet current demands but anticipate future challenges in mechanical engineering.

Choosing the Right Double Cardan Universal Joint Factory Partner

Selecting a reliable double cardan universal joint factory as a supplier can transform your project's success. Look for facilities with a proven track record, transparent certifications, and responsive customer service. Many such factories offer value-added services like prototyping, just-in-time delivery, and technical support to aid integration into existing systems. The double cardan universal joint's ability to handle up to 30 degrees of misalignment makes it ideal for complex assemblies, but partnering with an experienced factory ensures compatibility with your specific torque requirements. In an era where precision is paramount, these factories contribute to safer, more efficient machinery worldwide. By prioritizing factories that emphasize ethical labor practices and environmental responsibility, you support a sustainable supply chain while securing top-tier components for your operations.

Future Trends in Double Cardan Universal Joint Manufacturing

Looking ahead, the landscape of a double cardan universal joint factory is evolving with technological advancements. The integration of 3D printing for rapid prototyping and AI-driven quality checks promises even greater efficiency and customization. As electric vehicles gain prominence, factories are adapting designs to suit the unique demands of EV drivetrains, focusing on reduced noise and higher efficiency. Global supply chain dynamics may influence material sourcing, pushing factories toward localized production to mitigate risks. Despite these changes, the core principle remains: delivering double cardan universal joints that empower innovation across industries. For engineers and manufacturers, staying informed about these trends ensures they remain at the forefront of mechanical reliability and performance.

This comprehensive overview underscores why a double cardan universal joint factory is more than just a production site—it's a cornerstone of engineering excellence. With ongoing advancements, these facilities continue to drive the machinery that powers our world forward.